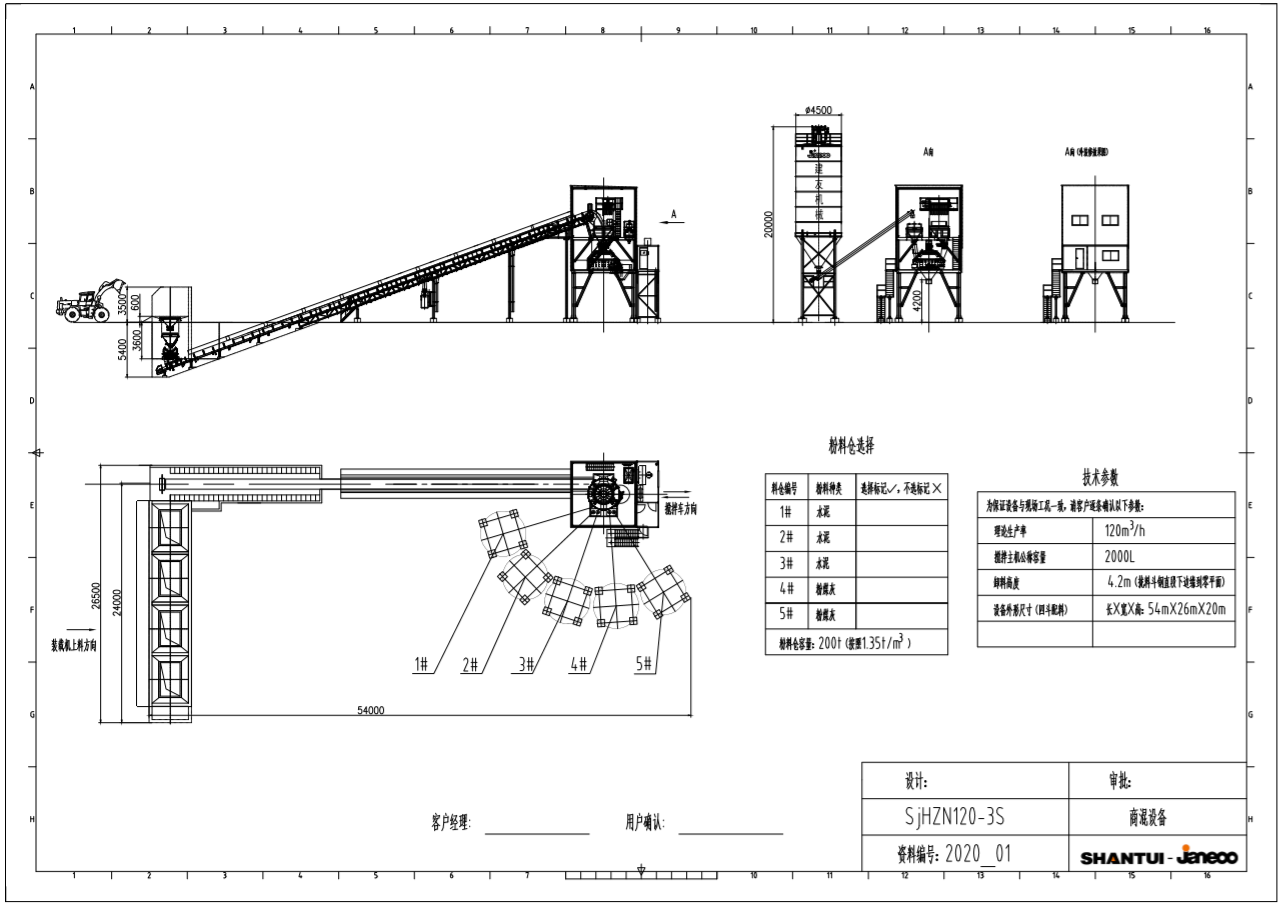

S nhepfenyuro SjHZN120S

SjHZS120M kugadzirisa

1. Hunhu:

1.1.Heavy-duty frame structure ine yakakwirira kugadzikana kwese;

1.2.Yakakura nzvimbo yemukati kuitira nyore kugadzirisa;

1.3.negative pressure pulse back ichiridza guruva kubviswa,

kushandiswa zvakare kwetsvina, kuita kwakanakisa kwezvakatipoteredza;

Zvishandiso : Yakagadzirirwa kugadzirira-kusanganisa kongiri kugadzirwa.

2. Zvakanakira

2.1 Yakagadzikana chimiro chikuru

1. Chitarisiko chinopindirana uye chakanaka, uye nenzvimbo huru yekuchengetedza mukati.

2. Yakakura simbi furemu chimiro chikuru, inonzwisisika marongerwo, yakagadzikana chimiro.

2.2 Yakavimbika aggregate batching system

2.3 Yakanyanya Kushanda musanganiswa

2.4 Yakanyanya kunyatso metering system

2.5 Nyore kuchengetedza bhandi conveyor system

2.6 Air control system ine dhizaini inonzwisisika

2.7 Yakanyanya kunaka yekushandisa tekinoroji

SjHZS120M kugadzirisa

| Aihwa. | Tsanangudzo | Item | Qty | Remark |

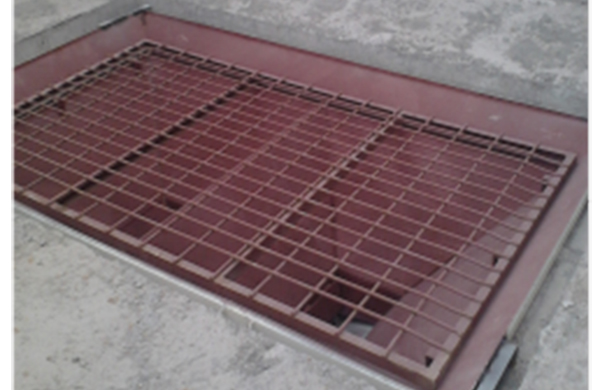

| 1 | Aggregates batching system (4 hoppers yepasi mhando) | Hopper yekuchengetera | 4 | 2 vibrator ye2 jecha hoppers |

| Huremu hopper (2000kg±2%) | 4 | |||

| humburumbira | 3x4 | |||

| Sensor | 3x4 | |||

| Bhandi muchina (B:1000mm,P:5.5KW) | 1 | |||

| 2 | Inclined bhandi muchina | Main rutsigiro | 1 |

|

| Kutyaira mudziyo (功率:37kW) | 1 | |||

| Bhandi (B:1000mm) | 1 | |||

| Mvura yekugeza mudziyo | 1 | |||

| 3 | Main building | Main chimiro (2 layers chikuva) | 1 |

|

| Kuburitsa hopper | 1 | |||

| Bag mhando sefa | 1 | |||

| Decoration | 1 | |||

| 4 | vertical planetary mixer | V:2.0 m3(P:90kW) | 1 |

|

| Hydraulic chimiro | 1 | |||

| Centralized lubrication system | 1 | |||

| 5 | Hopper yepakati | Hopper yekuchengetera | 1 |

|

| vibrator | 1 | |||

| humburumbira | 2 | |||

| 6 | Simende weighing system | Weighing hopper (1000kg±1%) | 1 |

|

| sensor | 3 | |||

| Kuburitsa valve (DN300) | 1 | |||

| vibrator | 1 | |||

| 7 | Powder weighing system

| Weighing hopper (400kg±1%) | 1 |

|

| sensor | 3 | |||

| Kuburitsa valve (DN300) | 1 | |||

| vibrator | 1 | |||

| 8 | Mvura yekuyera system | Weighing hopper (500kg±1%) | 1 |

|

| sensor | 1 | |||

| kuburitsa vharafu (DN150) | 1 | |||

| Pombi yemvura | 1 | |||

| Weighvhavha (DN80) | 1 | |||

| Mapombi ekuyera | 1 | |||

| 9 | Additive weighing system | Weighing hopper (50kg±1%) | 1 | PE additive tank |

| sensor | 1 | |||

| Kubvisa valve | 1 | |||

| Kuchengetedza tangi (V: 10m3) | 2 | |||

| Pombi yekuwedzera | 2 | |||

| Mapombi ekuyera | 2 | |||

| 10 | Pneumatic system | Mhepo compressor (kutamiswa: 1.6 m3/min) | 1 |

|

| tangi yemvura 1m3+0.3m3 | 1套 | |||

| Sefa uye vharafu | 1 | |||

| 11 | Imba yekudzora | decoration | 1 |

|

| Donhodzo remhepo | 1 | |||

| 12 | Electrical system | software | 1 | |

| Industrial komputa uye monitor | 1 | |||

| UPS simba | 1 | |||

| Printer | 1 | |||

| Tafura yekushanda | 1 | |||

| Electrical carbin uye | 1 | |||

| Monitoring system (1 yekutarisa + 4 kamera) | 1 | |||

| Optional | ||||

| Aihwa. | Tsanangudzo | Item | QTY | Remark |

| 13 | Cement silo | 200t | 5 | Cement density 1.35t/m3 |

| Maintenance platform | 1 |

| ||

| 14 | Accessoies | 24㎡ sefa | 5 |

|

| Vavhavha yakachengeteka pamusoro | 5 | |||

| Level mita | 2x5 | |||

| Arch breaker | 5 | |||

| Manual valve | 5 | |||

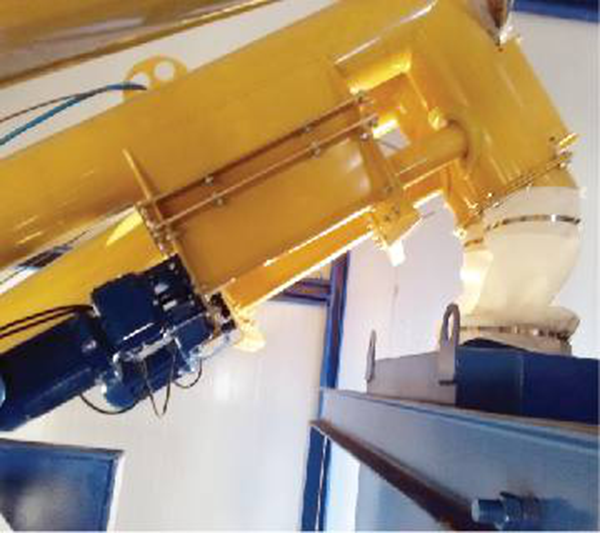

| 15 | Screw conveyor | φ273X11m | 3 | simende |

| φ219X11m | 2 | upfu | ||