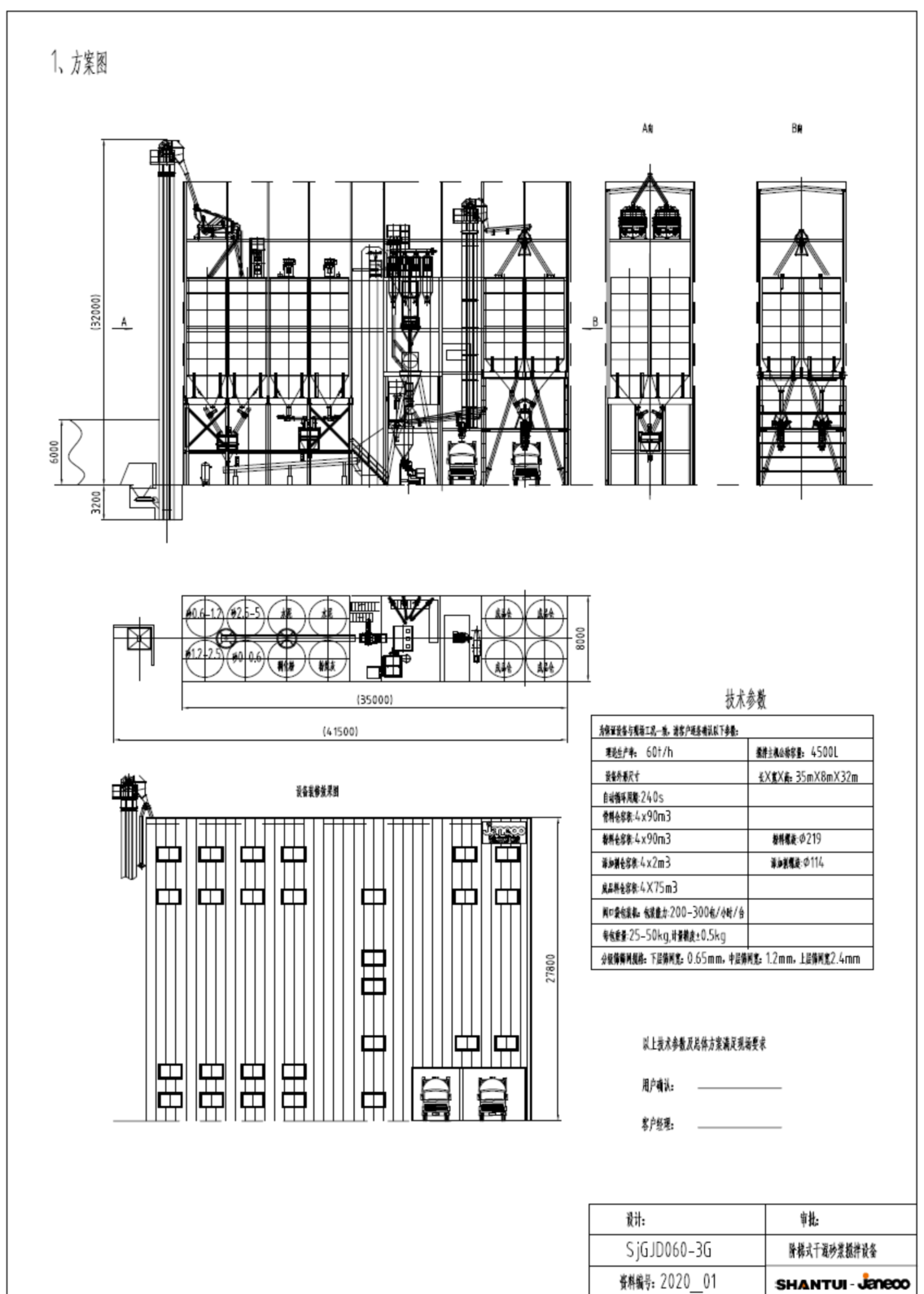

SjGJD060-3GStepped Type Dry Mortar batching chirimwa

Main specifications

1.main specifications

Theoretical kubereka 60t/h

Musanganisi SjGD4500-5B

aggregates kuyera kurongeka ± 2%

Cement kuyera kurongeka ±1%

kuwedzera kuyera kuyera ± 0.5%

Jecha silo vhoriyamu 4X90m3

Cement silo vhoriyamu 4X90m3

Wedzera silo vhoriyamu 4X2m3

Kurongedza kugona 200-300bags/h/set

Simba rose 330kW

1.Sand hoisting elevator

| Type | TB60 |

| Hoist speed | 1.1m/s |

| Theoretical kugona | 60m3/h |

| Motor power | 15kW |

2.Graded sikirini

| Motor power | 2x3.6kW |

| graded layer | 3 layers |

3.Sand silo

| Volume | 90m3 |

| Diameter | 3.4m |

4.Cement silo

| Volume | 90m3 |

| Diameter | 3.4m |

5.Additive silo

| Volume | 2m3 |

| Size | 0.9x0.9m |

6.Production silo

| Volume | 75m3 |

| Diameter | 3.4m |

7.Cement batching screw conveyor

| Diameter | 219mm |

| Capacity | 60t/h |

| Motor power | 5.5kW |

8.Aggregates kuyera hopper

| type | electronic scale |

| Max kukosha | 4000kg |

| Kururama | ±2% |

9.cement measuring hopper

| Mixer | SjGD4500-5B |

| Max kukosha | 1500kg |

| Kururama | ±1% |

10.additive measuring hopper

| type | electronic scale |

| Max kukosha | 150kg |

| Kururama | ±0.5% |

11.musanganiswa elevator

| type | TB110 |

| pressure | 1.1m/s |

| capacity | 110m3/h |

| simba remotokari | 22kW |

12.Mixer system

| Mixer | SjGD4500-5B |

| simba remotokari | 90kw |

| blade power | 4x5.5Kw |

13.packing machine

| kurongedza kugona | 200 ~ 300 mabhegi/h/seti |

| chimwe nechimwe chinorema | 25 ~ 50Kg |

| kururama | ±0.5Kg |

14.production sikuruu conveyor 1 pamberi pekusimudza

| type | GX400 |

| capacity | 42m3/h |

| simba remotokari | 15kW |

15.production screw conveyor 2 muhuwandu

| type | GX400 |

| capacity | 42m3/h |

| simba remotokari | 11kW |

16.production sikuruu conveyor 3 pashure elevator

| type | GX400 |

| capacity | 42m3/h |

| simba remotokari | 11kW |

17.Kuwanda muchina

| capacity | 100t/h |

| flexible chinhambwe chekuburitsa gedhi | 1200mm |

| simba remotokari | 0.55kW |

| Sefa feni simba | 2.2kW |

18.Production hoist elevator

| TB60 | TB60 |

| hoist speed | 1.1m/s |

| capacity | 60m3/h |

| simba remotokari | 15kW |

18.Sefa

| Main buliding sefa mhando | HMC48 |

| simba | 4Kw |

| kurongedza sefa mhando | HMC48 |

| simba | 4Kw |

19.air compressor simba:37Kw

20.electrical system

Iyo sisitimu inofambiswa neac 380V uye 50Hz matatu-chikamu chechina (shanu) waya system.

21.computer control

auto uye manual

22.cycle nguva

| auto | 240s |

Tsanangudzo

SjGJD060-3G yakatsika-mhando yakaoma dhaka batching midziyo inotora yakatsikwa-mhando chimiro, ine hunhu hwekubereka hukuru, kugadzikana uye kuvimbika, uye inogona kushandiswa kusanganisa yakajairika dhaka rakaoma uye yakaoma yakaoma. single horizontal shaft gejo-mhando musanganisi, ine hunhu hwepamusoro musanganiswa kunyatsoshanda uye yakakwirira kusanganisa kufanana, uye chiyero chekusanganisa chinogona kusvika 1: 10000.

Configuration

| Zvigadzirwa zvakajairika | ||||

| Aihwa. | Tsanangudzo | Item | Qty | Remark |

| 1 | Dry sand hoist mudziyo | 1 |

| |

| (约33m, 15 KW)revheti | 1 | |||

| chikuva uye manera | 1 | |||

| chitubu chekudya uye kuburitsa | 1 | |||

| 2 | graded screen | 1 |

| |

| 3. masikirini mambure: pasi: 0.65mmmid: 1.2mm, kumusoro 2.4mm | 2 | |||

| chitubu chekudya uye kuburitsa | 1 | |||

| 3 | 砂仓除尘及出料sand silo | 1 |

| |

| kuburitsa chute | 4 | |||

| (DN300) valve | 4 | |||

| pneumatic valve | 4 | |||

| HMC48 sefa | 1 | |||

| 4 | simende uye jecha kuyera chikero | 1 |

| |

| 3000kg jecha rekuyera chiyero chikuru 3000kg | 1 | |||

| pressure sensor | 3 | |||

| (DN250) pneumatic valve | 1 | |||

| vibrator MVE60/3 | 1 | |||

| 1500kg | 1 | |||

| pressure sensor | 3 | |||

| pneumatic valve (DN250) | 1 | |||

| vibrator MVE60/3 | 1 | |||

| 5 | musanganiswa wekutumira system | 1 |

| |

| sikuruu GX500 | 1 | |||

| accessories | 1 | |||

| 6 | musanganiswa hoist elevator | 1 |

| |

| TB110 elevator (约20m,22kw) | 1 | |||

| chute yekudyisa uye yekuburitsa gedhi | 1 | |||

| 7 | additive feeding uye tangi rekuchengetedza | 1 |

| |

| additive silo (V:2m3) | 4 | |||

| rotary level mita | 4 | |||

| manual valve (DN300) | 4 | |||

| pneumatic valve (DN150) | 4 | |||

| vibrator MVE60/3 | 4 | |||

| sefa system | 1 | |||

| 8 | chikero chekuyeresa chekuwedzera | 1 |

| |

| hukuru hunokosha 150kg | 1 | |||

| pressure sensor | 3 | |||

| pneumatic valve (DN250) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 9 | additive hoist device | 1 |

| |

| rutsigiro | 1 | |||

| njanji | 1 | |||

| hoist cage | 1 | |||

| electric hoist 2000Kg | 1 | |||

| 10 | manual feeding device | 1 |

| |

| manual feeding silo | 1 | |||

| pneumatic valve (DN200) | 1 | |||

| 11 | pakati-kuchengetera hopper | 1 |

| |

| hopper body | 1 | |||

| pressure sensor | 1 | |||

| pneumatic valve (DN300) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 12 | kusanganisa system (V:4500L) | 1 |

| |

| kutyaira mudziyo 90KW | 1 | |||

| kusanganisa mudziyo | 1 | |||

| high speed rotary scraper 5.5KW | 4 | |||

| gate rekubuditsa | 1 | |||

| kusanganisa tank | 1 | |||

| muenzaniso mudziyo | 1 | |||

| 13 | hopper yekuchengetera | 1 |

| |

| hopper body | 1 | |||

| vibrator MVE 60/3 | 2 | |||

| impelled feeder | 1 | |||

| rotary level mita | 1 | |||

| pneumatic 4 phase valve | 1 | |||

| 14 | zvakawanda uye kurongedza muchina | 1 |

| |

| yakawanda muchina | 1 | |||

| hopper body | 1 | |||

| rotary level mita | 2 | |||

| vibrator MVE 60/3 | 2 | |||

| kaviri kubuda kurongedza muchina | 1 | |||

| bhandi muchina (L = 2500m, B = 650mm, 2.2kw) | 1 | |||

|

| ||||

| 15 | kugadzirwa hoist uye kuburitsa system | 1 |

| |

| elevator (19m, 15kw) | 1 | |||

| manera nechikuva | 1 | |||

| chute yekudyisa uye yekuburitsa gedhi | 1 | |||

| rotary distributer | 1 | |||

| 16 | kugadzirwa kwakawanda | 1 |

| |

| chute yekubuda | 4 | |||

| pneumatic kuisa vharafu | 4 | |||

| pneumatic valve (DN300) | 4 | |||

| shanduko hopper | 1 | |||

| yakawanda muchina | 2 | |||

| 17 | Main kuvaka sefa mudziyo | 1 |

| |

| Pulse back flush sefa 36m2 4KW | 1 | |||

| sefa mapaipi | 1 | |||

| manual valve (DN150) | 2 | |||

| pneumatic valve (DN250) | 1 | |||

| 18 | kurongedza sefa mudziyo | 1 |

| |

| Pulse back flush sefa 36m2 4KW | 1 | |||

| manual valve (DN150) | 1 | |||

| sefa mapaipi | 1 | |||

| 19 | pneumatic system | 1 |

| |

| air compressor | 1 | |||

| tangi yekuchengetera 1m3 | 1 | |||

| tangi yekuchengetera 0.3m3 | 2 | |||

| main sefa | 1 | |||

| dryer | 1 | |||

| majoini | 1 | |||

| 20 | control system | 1 |

| |

| kombiyuta yemaindasitiri | 1 | |||

| software | 1 | |||

| zvikamu zvemagetsi | 1 | |||

| main frequency inverter | 1 | |||

| LED monitor | 1 | |||

| printer | 1 | |||

| Magetsi | 1 | |||

| tafura yekushanda | 1 | |||

| carbinet yemagetsi | 1 | |||

| waya netambo | 1 | |||

| 21 | hurongwa hwekutarisa | 1 |

| |

| kamera kamera | 4 | |||

| amera lens | 4 | |||

| 19 LED yekutarisa | 1 | |||

| isa DV | 1 | |||

| 22 | control room | 1 |

| |

| control room frame | 1 | |||

| mukati nekunze kushongedzwa | 1 | |||

| mwenje uye chinja | 1 | |||

| donhodzo remhepo | 1 | |||

| 23 | Main simbi chimiro | 1 |

| |

| chassis | 1 | |||

| manera | 1 | |||

| tsigira gumbo | 1 | |||

| Zvishandiso zvekutakura zvekuchengetedza | ||||

|

|

| |||

| 24 | simende sikuruu conveyor | φ219-2140 | 4 |

|

| 25 | 机additive screw conveyor | Ø114-2000 | 2 |

|

| 26 | 机additive screw conveyor | Ø114-1300 | 2 |

|

| 27 | kugadzira sikuruu conveyor (pamberi pe lift) | GX400-6500 | 1 |

|

| 28 | kugadzira sikuruu conveyor (mushure memuchina wakawanda uye elevator) | GX400-5000 | 2 |

|

| 29 | raw material yekuchengetera bhini (现场制作) | 1 |

| |

| jecha silo: dia 3.4m, V 90m3 | 4 | |||

| 粉仓 silo silo: dia 3.4m, V 90m3 | 4 | |||

| manual valve | 4 | |||

| level mita | 8 | |||

| arch breaker | 4 | |||

| manual valve | 4 | |||

| level mita | 8 | |||

| vharafu yakachengeteka | 4 | |||

| pulse back flush sefa | 4 | |||

| simbi yekugadzira tsigiro | 1 | |||

| 30 | kugadzirwa kwekuchengetedza silo |

| ||

| silo:dhiya 3.4m,V:75m3 | 4 | |||

| arch breaker | 4 | |||

| manual valve (DN300) | 4 | |||

| rotary level mita | 8 | |||

| (1.5kw) pulse back flush sefa | 1 | |||

| simbi yekugadzira tsigiro | 1 | |||

| 31 | decoration | 1 |

| |

| decoration 2500m2, (0.5mm) | 1 | |||

| furemu yemuviri, mahwindo nemagonhi | 1 | |||