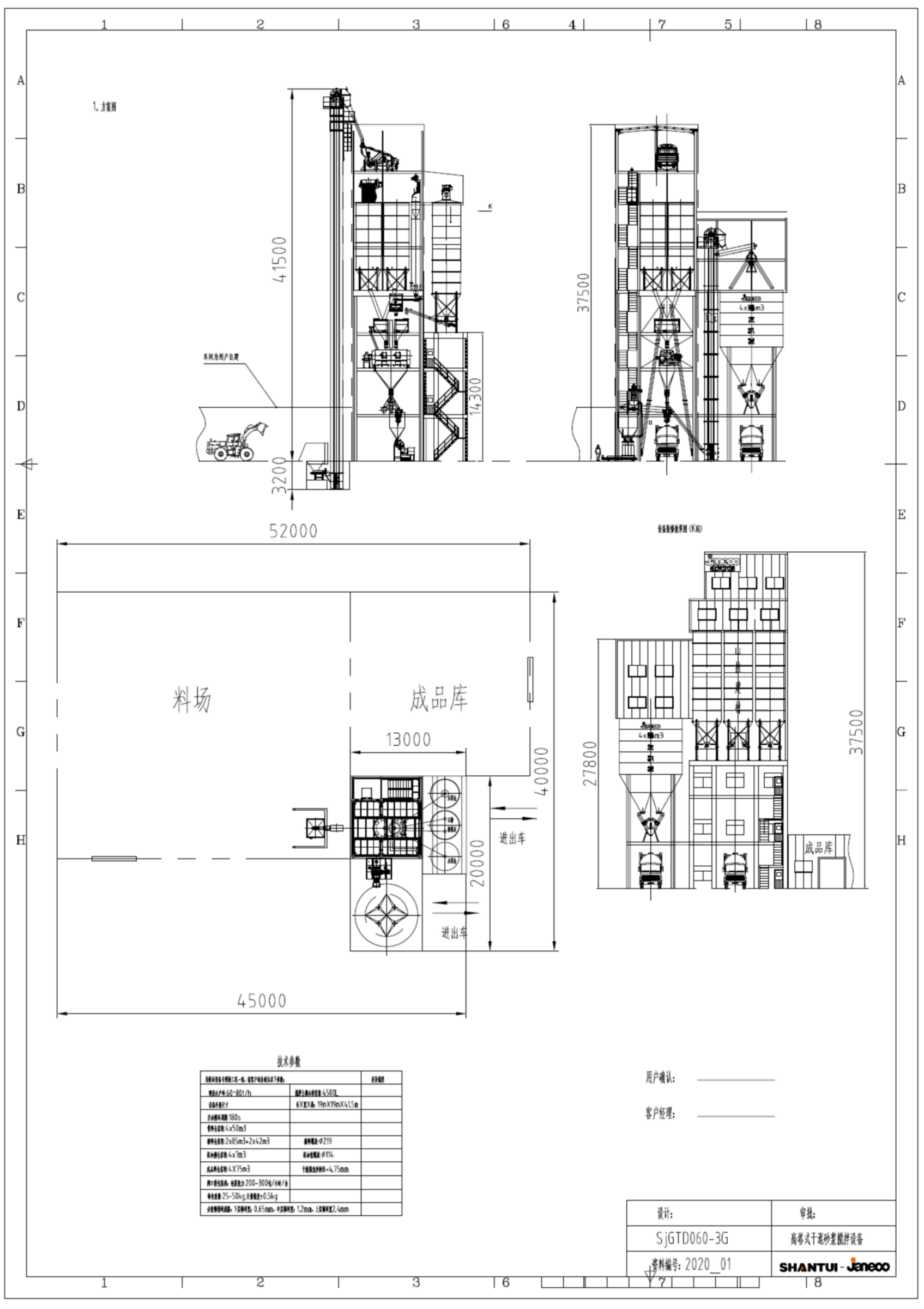

SjGTD060-3G Shongwe Type Dry Mortar Batching Plant

Main specifications

1.main specifications

Theoretical kubereka 60-80t/h

Musanganisi SjGD4500-5B

aggregates kuyera kurongeka ± 2%

Cement kuyera kurongeka ±1%

kuwedzera kuyera kuyera ± 0.5%

Jecha silo vhoriyamu 4X50m3

Cement silo vhoriyamu 2X85m3+2X42m3

Cement silo vhoriyamu 2X85m3+2X42m3

Kurongedza kugona 200-300bags/h/set

Kurongedza kugona 200-300bags/h/set

1.Sand hoisting elevator

| Type | TB60 |

| Hoist speed | 1.1m/s |

| Theoretical kugona | 60m3/h |

| Motor power | 18.5kW |

2.Sand batching chute pipe

| chute diameter | 323mm |

3.Cement batching screw conveyor

| screw diameter | 219mm |

| capacity | 60t/h |

| Motor power | 7.5KW |

4.Fly madota batching sikuruu conveyor

| screw diameter | 219mm |

| capacity | 60t/h |

| Motor power | 7.5kW |

5.Thickening upfu batching sikuruu conveyor

| screw diameter | 219mm |

| capacity | 60t/h |

| Motor power | 7.5kW |

6.aggregates kuyera hopper

| type | electronic scale |

| Max kukosha | 4000kg |

| kururama | ±2% |

7.cement kuyera hopper

| type | electronic scale |

| Max kukosha | 2000kg |

| kururama | ±1% |

8.additive measuring hopper

| type | electronic scale |

| Max kukosha | 150kg |

| kururama | ±0.5% |

9.mixer system

| Mixer | SjGD4500-5B |

| simba remotokari | 90KW |

| blade power | 4x5.5KW |

10.impeller feeder

| dhayamita | 400mm |

| simba remotokari | 3KW |

| capacity | 50m3/h |

11.packing machine

| kurongedza kugona | 200 ~ 300 mabhegi/h/seti |

| chimwe nechimwe chinorema | 25 ~ 50Kg |

12.bhandi muchina

| bhandi muchina | 2KW |

13.production screw conveyor

| type | GX500 |

| capacity | 70m3/h |

| simba remotokari | simba remotokari |

14 yakawanda muchina

15.production hoist elevator16.2 kugadzira sikuruu conveyor 217.electrical system19.electrical system

Iyo sisitimu inofambiswa neac 380V uye 50Hz matatu-chikamu chechina (shanu) waya system.

20.computer control

kudzora komputa

21.cycle nguva

motokari:180s

| capacity | 100t/h |

| flexible chinhambwe chekuburitsa gedhi | 1200mm |

| simba remotokari | 0.55kW |

| sefa fan simba | 2.2kW |

| type | TB110 |

| hoist speed | 1.1m/s |

| capacity | 110m3/h |

| simba remotokari | 22kW |

| screw diameter | GX500 |

| capacity | 70m3/h |

| simba remotokari | 7.5KW |

| mhepo compressor simba | 37kW |

| pressure | 7.5KW |

Tsanangudzo

Sjgtd060-3g yakaoma dhaka batching midziyo inotora shongwe chimiro, ine hukuru hukuru, kuchengetedza simba uye kuchengetedzwa kwezvakatipoteredza, yakagadzikana uye yakavimbika hunhu, inonyanya kushandiswa kusanganisa yakajairika dhaka rakaoma.

Midziyo mikuru inotora shongwe chimiro, ine 4 jecha silos, 4 hupfu silos, 4 ekuwedzera silos uye 4 akapedza chigadzirwa silos.Jecha rekushandisa waya zvakajairika rinosimudzwa nemushini webucket wochengetwa mubhini rejecha mushure mekuongororwa. Poda inounzwa mubhini rehupfu ne tanker rakawanda. Iyo yekuwedzera inosimudzwa kudura rekuwedzera nemagetsi ekusimudza mudziyo uye inoiswa mudura rekuwedzera nemawoko. .

Jecha rinotora pombi inotsvedza batching, hupfu zvinhu, zvinowedzerwa zvinotora spiral conveyor batching.

Bhakiti rekuyeresa rinotora chikero chemagetsi kuyera, icho chine kuyera kwepamusoro uye kukanganisa kudiki.

Iyo yekudzora sisitimu inotora manyorero uye otomatiki control.Iyo system ine yakakwana yekuzvivharira uye yepakati-kuvhara mabasa kuti ive nechokwadi chechokwadi uye chakavimbika kushanda kwehurongwa, uye ine zvakajairika kuona kukanganisa uye mabasa aramu.

Configuration

| Zvigadzirwa zvakajairika | ||||

| Aihwa. | Tsanangudzo | Item | Qty | Remark |

| 1 | yakaoma jecha hoist mudziyo | 1 |

| |

| elevator (42m) | 1 | |||

| manera nechikuva | 1 | |||

| chitubu chekudya uye kuburitsa | 1 | |||

| 2 | graded screen device | 1 |

| |

| 3 akaturikidzana vibrating skrini (2x3.6KW) yakaderera: 0.65mm, yepakati: 1.2mm, kumusoro 2.4mm | 1 | |||

| chute pipe | 1 | |||

| 3 | jecha silo sefa | 1 |

| |

| chute pombi φ325 | 4 | |||

| pneumatic valve (DN300) | 4 | |||

| isa vharafu | 4 | |||

| pulse back flush filter HMC48 | 1 | |||

| 4 | jecha scale | 1 |

| |

| hukuru hunokosha 4000kg | 1 | |||

| pressure sensor | 3 | |||

| sensor majoini | 3 | |||

| pneumatic valve (DN300) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 5 | simiti muyero | 1 |

| |

| kukosha kwepamusoro 2000kg | 1 | |||

| pressure sensor | 3 | |||

| sensor majoini | 3 | |||

| pneumatic valve (DN300) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 6 | additive scale | 1 |

| |

| hukuru hunokosha 150kg | 1 | |||

| pressure sensor | 3 | |||

| pneumatic valve (DN200) | 1 | |||

| vibrator MVE60/3 | 1 | |||

| 7 | manual feeding device | 1 |

| |

| kudyisa hopper uye kuvhara | 1 | |||

| pneumatic valve (DN200) | 1 | |||

| 8 | additive filter | 1 |

| |

| pneumatic valve (DN150) | 4 | |||

| additive silo sefa | 1 | |||

| 9 | kusanganisa system (V:4500L) | 1 |

| |

| kutyaira mudziyo 90KW | 1 | |||

| kusanganisa mudziyo | 1 | |||

| high speed rotary scraper 5.5KW | 4 | |||

| gate rekubuditsa | 1 | |||

| kusanganisa tank | 1 | |||

| muenzaniso mudziyo | 1 | |||

| 10 | Main hopper uye yakawanda | 1 |

| |

| hopper body | 1 | |||

| vibrator MVE 60/3 | 2 | |||

| impelled feeder | 1 | |||

| pneumatic 4 zvikamu | 1 | |||

| rotary level mita ILTC0 | 1 | |||

| yakawanda muchina | 1 | |||

| 11 | kugadzira kurongedza muchina |

|

| |

| hopper body | 1 | |||

| rotary level mita ILTC0 | 2 | |||

| vibrator MVE 60/3 | 2 | |||

| 2 inobuda yekurongedza muchina | 1 | |||

| kugadzira bhandi muchina (B = 650mm, 2.2kw) | 1 | |||

| 12 | kugadzirwa hoist uye distributer | 1 |

| |

| elevator (24m, 15kw) | 1 | |||

| manera nechikuva | 1 | |||

| chitubu chekudya uye kuburitsa | 1 | |||

| sikururu rutsigiro | 1 | |||

| rotary distrubuter 0.75KW | 1 | |||

| 13 | kugadzirwa kwakawanda | 1 |

| |

| pneumatic kuisa vharafu | 4 | |||

| pneumatic valve (DN300) | 4 | |||

| tansition hopper | 1 | |||

| yakawanda muchina | 1 | |||

| 14 | kurongedza sefa mudziyo | 1 |

| |

| pulse back flush filter (1.5kw) | 1 | |||

| sefa mapaipi | 1 | |||

| manual valve (DN150) | 1 | |||

| 15 | pneumatic system | 1 |

| |

| air compressor | 1 | |||

| tangi yekuchengetera 1m3 | 1 | |||

| Kuchengetedza tangi 0.3m3 | 2 | |||

| main sefa | 1 | |||

| dryer | 1 | |||

| majoini | 1 | |||

| 16 | control system | 1 |

| |

| kombiyuta yemaindasitiri | 2 | |||

| software | 2 | |||

| zvikamu zvemagetsi | 1 | |||

| 19LED yekutarisa | 2 | |||

| printer | 1 | |||

| magetsi | 1 | |||

| tafura yekushanda | 1 | |||

| kabati yemagetsi | 1 | |||

| waya netambo | 1 | |||

| 17 | hurongwa hwekutarisa | 1 |

| |

| makamera emavara | 4 | |||

| cemera lens | 4 | |||

| LED monitor | 1 | |||

| isa DV | 1 | |||

| 18 | Main simbi chimiro |

|

| |

| chassis | 1 | |||

| manera | 1 | |||

| rutsigiro | 1 | |||

| kutakura kwekuchengetedza uye kushongedza kwekunze | ||||

| 19 | simende sikuruu conveyor | φ219X6000mm | 2 |

|

| 20 | simende sikuruu conveyor | φ219X5000mm | 2 |

|

| 21 | 机additive screw conveyor | φ114x3000mm | 2 |

|

| 22 | additive screw conveyor | φ114x2000mm | 2 |

|

| 23 | kugadzira sikuruu conveyor | GX500-4500 | 1 |

|

| 24 | kugadzira sikuruu conveyor | GX500-2500 | 1 |

|

| 25 | Jecha rekuchengetedza silo | 4 |

| |

| V:50m3 | 4 | |||

| manual valve | 4 | |||

| rotary level mita | 8 | |||

| 26 | siro yekuchengetera simende | 2 |

| |

| V:85m3 | 2 | |||

| arch breaker | 2 | |||

| manual valve (DN300) | 2 | |||

| rotary level mita | 4 | |||

| vharafu yakachengeteka | 2 | |||

| silo kumusoro pulse kumashure flush sefa | 2 | |||

| 27 | siro yekuchengetera simende | 1 |

| |

| V: 2x42m3, insulation silo | 1 | |||

| arch breaker | 2 | |||

| manual valve (DN300) | 2 | |||

| rotary level mita | 4 | |||

| vharafu yakachengeteka | 2 | |||

| silo kumusoro pulse kumashure flush sefa | 2 | |||

| 28 | kugadzirwa kwekuchengetedza silo | 1 |

| |

| V: 4x75m3, insulation silo | 1 | |||

| pulse back flush filter (1.5kw) | 1 | |||

| arch breaker | 4 | |||

| manual valve | 4 | |||

| rotary level mita | 8 | |||

| 29 | additive silo | 4 |

| |

| V:7m3 | 4 | |||

| rotary level mita | 4 | |||

| vibrator MVE 60/3 | 4 | |||

| manual valve (DN300) | 4 | |||

| 30 | electric hoist mudziyo | 1 |

| |

| electric hoist | 1 | |||

| njanji, keji | 1 | |||

| 31 | decoration | decoration 1500m2, (0.5mm) | 1 |

|

| body frame | 1 | |||